Material of the profile: GI or color steel

Thickness range: 0.3-0.8mm

Main motor power:5.5kw, AC motor, motor inside of main machine (Brand: Guomao of China) (according the final design)

Machine Voltage, Frequency, Phase: 380 V, 50 Hz, 3Phase

Roll station: about 18 stations (according the final design)

Roller material:ASTM1045 chrome plated surface with chrome,CNC,

Shaft diameter: ¢70mm material: SAE1045 with quenching and tempering

Machine roll forming speed:not less than 30m/min

Transmission: by chain, one inch, single line

Roll former has leveling bolts in the base for adjust the leveling

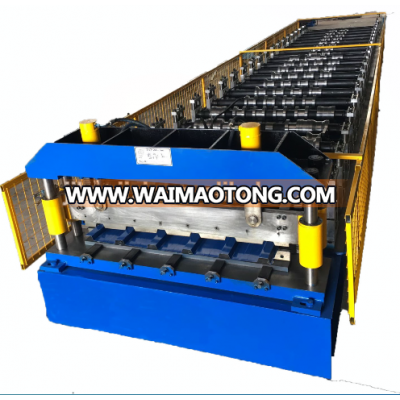

Machine base frame adopt H beam welding steel

In the main roll forming machine have 2 buttons for urgency stop if happen any malfunction.

Machine adopt new station to make machine more strong

To avoid accidents,all of drive part adopt protect cover

Color of machine: Blue and yellow (or base on customer request)

Quantity: 1